Courier counter staff can spot a non-compliant battery package from ten metres – and so can regulators. Lithium battery shipping regulations leave no room for guesswork: misdeclare a pack and it may return to your warehouse or trigger an investigation. To stay compliant you must (1) identify the battery chemistry and configuration, (2) apply the mode-specific packaging, labelling and documentation rules, and (3) keep trained, competent people in charge of every shipment.

These rules are strict for good reason. A damaged cell can enter thermal runaway in seconds, turning an aircraft hold or container stack into an uncontrollable fire. That is why the UN has classified lithium batteries as Class 9 hazardous material and why air, sea, road and rail authorities publish their own, frequently updated, directives.

This guide translates those directives into clear, practical actions. We will walk you through identification, regulatory mapping, quantity calculations, packaging, marks and labels, paperwork, carrier acceptance, staff training and special scenarios such as damaged or waste batteries. Follow the steps and you will ship with confidence, avoid penalties, and keep your supply chain moving.

1. Identify the Lithium Battery You Are Shipping

Everything that follows—packaging choices, labels, documents—hinges on getting this first step right. Regulators expect you to know exactly what sits inside the box, down to the chemistry, size and state-of-charge. A hasty guess here is the fastest route to refusal at the carrier counter.

1.1 Differentiate between lithium-ion and lithium-metal chemistries

- Lithium-ion (rechargeable)

- Proper shipping name: Lithium ion batteries

- UN3480 (batteries alone) or UN3481 (batteries contained in or packed with equipment)

- Common in phones, e-bikes, power tools

- Lithium-metal (non-rechargeable)

- Proper shipping name: Lithium metal batteries

- UN3090 (batteries alone) or UN3091 (with/contained in equipment)

- Found in watches, medical sensors, key fobs

Lithium-metal cells use solid lithium anodes and carry a higher fire risk when short-circuited; the regulations therefore treat them separately and, in some cases, more strictly.

1.2 Determine the shipment configuration: alone, packed with, or contained in equipment

Configuration dictates the IATA Packing Instruction (PI 965–970) you must follow and the level of control applied by sea (IMDG) and road/rail (ADR/RID).

- Batteries alone – e.g., spare drone packs ordered online (PI 965 / 968).

- Batteries packed with equipment – camera plus a spare battery in the same carton (PI 966 / 969).

- Batteries contained in equipment – smartphone sealed in its retail box (PI 967 / 970).

Get this wrong and you may exceed quantity limits without realising.

1.3 Confirm test compliance and battery specifications

Before a cell can move internationally it must have passed the UN 38.3 series of abuse tests. The supplier must provide a test summary and you must keep it accessible for anyone in the supply chain.

Key numbers:

- Watt-hours (Wh) for ion cells:

Wh = Voltage × Amp-hours (Ah)- Example: 11.1 V × 4.5 Ah = 49.95 Wh

- Lithium content (g) for metal cells is normally declared by the manufacturer.

Additional air requirement: lithium-ion batteries shipped without equipment (UN3480) or (UN3481) packed with equipment, must not exceed 30 % state-of-charge. Record the SoC on your checklist—airlines do spot checks, and non-conforming packs are immediately off-loaded.

2. Map the Regulations That Apply to Your Route and Mode

Rules change the moment a shipment transfers from truck to aircraft or is lifted onto a feeder vessel. Before packaging even begins, plot the exact journey and pull the relevant rulebooks; the strictest provision always wins. The four core frameworks below shape most lithium battery shipping regulations faced by UK shippers.

2.1 Air transport: ICAO Technical Instructions / IATA DGR 2025 essentials

- Packing Instructions 965–970 set the tone.

- Section IA (fully regulated) and Section IB (limited relief) demand UN-spec outer packagings, hazard label 9A and the full Shipper’s Declaration.

- Section II offers simpler paperwork but caps each package at ≤ 2 batteries or ≤ 8 cells (metal) or 100 Wh (ion).

- Lithium-ion cells/batteries shipped alone must be ≤ 30 % state-of-charge and travel only on cargo aircraft.

- Lithium-ion cells/batteries packed with equipment must be ≤ 30 % state-of-charge but can go on either passenger or cargo aircraft depending on the weight of the batteries in the outer packaging.

- One overpack may hold up to multiple packages of Section II as long as the battery weight ceiling is respected and the battery mark remains visible.

- Airlines can impose tighter carrier variations—check the NOTOC or booking portal before tendering.

2.2 Sea freight: IMDG Code Amendment 41-22

Batteries travel as UN 3480/81 or UN 3090/91, Class 9, no packing group. Special Provisions 188, 230 and 389 decide whether simplified packaging and paperwork can be used; SP 188 mirrors IATA Section II limits. Stowage Code A requires “away from sources of heat”; segregation from class 1 explosives and class 2.1 flammables is mandatory. The next amendment (42-24) will tighten wording around damaged cells, so prepare now.

2.3 Road & rail (ADR/RID 2025)

Inside the UK and Europe, SP 188 again dominates: ≤ 2 g lithium metal or ≤ 100 Wh ion per cell to avoid full ADR. Packages moving under the exemption still need the lithium mark. When fully regulated, add “UN 3480, LITHIUM ION BATTERIES, 9” to the transport document and provide written driver instructions. The UK currently mirrors EU ADR with no extra derogations announced post-Brexit.

2.4 Postal and courier limitations in the UK

Royal Mail and Parcelforce only accept lithium batteries when contained in or packed with equipment, max four cells or two batteries per package, and they forbid damaged or recalled units. Loose batteries are banned from air-mail streams, which traps many online sellers—use a DG-approved courier instead.

2.5 Multimodal shipments and the “one document” approach

A Multimodal Dangerous Goods Note can satisfy both IMDG and ADR legs if every data field matches the maritime template. Never rely on it for an air segment: a separate IATA Shipper’s Declaration is non-negotiable, even when the physical pack remains sealed from door to door.

3. Calculate Quantity Limits and Select Compliant Packaging

The regulations do not let you cram “just one more” battery into a box; understanding what type of battery is beng shipped and the energy that is produces is vital for preventing repacking and costly flight delays. Once you know the figures, you can match them to the correct grade of packaging and the Packing Instruction referenced in the rulebooks above.

3.1 Work out watt-hours or lithium content to check thresholds

Under every mode of transport you must declare either watt-hours (for rechargeable lithium-ion) or lithium metal content (for non-rechargeable). The formula is straightforward:

Watt-hours (Wh) = Nominal Voltage (V) × Capacity (Ah)

If the capacity is listed in milliamp-hours, divide by 1 000 first.

| Typical device | UN number | Nominal V | Capacity (Ah) | Wh (approx.) | Regime triggered* |

|---|---|---|---|---|---|

| Smartwatch cell | UN3480 | 3.8 V | 0.7 Ah | 2.7 Wh | SP 188 / Section II |

| Smartphone pack | UN3481 | 3.7 V | 3.1 Ah | 11.5 Wh | SP 188 / Section II |

| Power-tool battery | UN3480 | 18 V | 5 Ah | 90 Wh | Section IB by air |

| E-bike module | UN3480 | 36 V | 14 Ah | 504 Wh | Section IA / full ADR |

*Assumes batteries shipped alone.

For lithium-metal cells the manufacturer will state grams of lithium. Stay below 1 g per cell or 2 g per battery to qualify for the lighter SP 188 treatment.

3.2 Choose UN-specification versus non-UN packaging

- UN-spec combination packagings (4G, 4GU, 4GV, etc.) are mandatory for any fully-regulated shipment (IATA Section IA, Section IB, IMDG outside SP 188, ADR full entry).

- Strong, rigid, non-UN cartons are acceptable for Section II air and SP 188 road/sea, provided they withstand a 1.2 m drop test and protect the contents from movement or short-circuit.

- Never reuse a fibreboard box unless it is still in perfect condition and closure instructions are followed exactly.

3.3 Follow the correct packing instruction step-by-step

- Isolate each cell or battery – tape terminals or slip them into an anti-static sleeve.

- Place in an inner packaging – blister tray, plastic bag or strong fibreboard.

- Add enough cushioning – foam chips or bubble wrap to stop movement.

- Fill voids so nothing rattles when shaken.

- Close the outer using the tape type and number of strips specified by the box manufacturer.

- Record the gross mass; ensure you are within the weight limits for the mode of transport.

3.4 Use combination packaging, overpacks and pallets correctly

An overpack is a protective layer—shrink-wrapped tray, fibreboard box, pallet—that groups two or more packages for ease of handling. You must:

- Mark the word “OVERPACK” and repeat or show the battery mark , or Class 9 labels, comply with the marking requirements.

- Ensure the total quantity inside still respects the PI or SP limits.

- Ensure that each pack within the overpack is compliant and correct marked & labelled.

- Leave airflow gaps when stretch-wrapping pallets; crushed cartons invite thermal issues and insurance claims.

4. Apply Mandatory Markings and Labels Accurately

You have done the maths and built a compliant box; now make sure the outside talks the same language as the carrier. Under lithium battery shipping regulations, a missing symbol can turn a legal shipment into prohibited cargo. Always print labels on weather-proof material, apply them on a contrasting background, and wipe the surface dry before sticking.

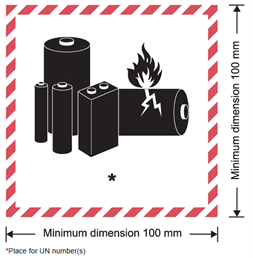

4.1 Battery mark versus Class 9 “Lithium Battery” label 9A

The everyday label for small consignments under 100 wh or under 2 gram is the battery mark must be applied.

Dimensions: standard 100 mm × 100 mm; may be reduced to 100 mm × 70 mm on packs under 30 kg.

Contents: red-hatched border, the UN number(s) (e.g. UN3480, UN3481)

Use this mark when shipping under IATA Section II, IMDG/ADR SP 188 or Royal Mail’s “in equipment” allowance.

The Class 9 Lithium Battery hazard label 9A replaces, or in fully regulated cases accompanies, the mark when:

Shipping under IATA Section IA or IB;

Moving batteries that exceed SP 188 limits by sea or road;

An aircraft or vessel operator specifically requests it on overpacks or unit load devices.

4.2 Orientation arrows, limited quantity mark and overpack labelling

- Orientation arrows are not compulsory for batteries on their own, yet many shippers add them unnecessarily. Of course if Orientation arrows are already placed on the package design, this will ensure that the package will be correctly rotated.

- Overpacks must display the word “OVERPACK” ≥ 12 mm high and either show the marks/labels through transparent wrap or repeat them on the outside.

4.3 Common labelling mistakes and how to avoid them

Typical errors that stop freight at the handling depot:

| Common Errors | Ways to Avoid |

| Wrong or missing UN number. | Check UN numbers against the shippers declaration |

| Labels printed in inkjet that runs in rain. | Ensure you purchase labels from a reputable Dangerous Goods label provider |

| Marks & Labels hidden under stretch-wrap or corner boards. | Follow procedures outlined in the regulations |

| If multiple Overpacks – the pallet does not have an identification mark (required for Air) | Create a pre-dispatch checklist |

A two-minute label audit saves hours of repacking and protects your compliance record.

5. Complete the Required Documentation

Labels tell inspectors what is inside the carton, but paperwork proves you followed the rules in black and white. Each mode has its own form, layout, and signature requirements; mix them up and the carrier’s DG desk will put your freight on hold. Treat documentation as a final cross-check: if quantities, UN numbers or packing instructions clash with the box, something is wrong.

5.1 Shipper’s Declaration for Dangerous Goods (air)

ICAO/IATA demand a shippers declaration to have a red hash to higlight that dangerous goods are present. Most airlines request 2 copies of the shippers declaration, but some airlines require more copies e.g. Fedex & UPS. Following the requirements stipulated in the regulations is essential. The airlines will check all aspects. The most common reasons for your document being rejected are:

- Incomplete Addresses, Name, street, city, postcode (if common) and country are mandatory.

- Proper shipping name and UN number do not match regulations e.g.

UN3480, LITHIUM ION BATTERY. - Missing Hazard Class –

9 - Incorrect Packing Instruction – or not displaying if you hav

965 IA,IB. - Confusing Quantity and packing type e.g

4 × 90 Wh batteries in 4G fibreboard box. – We need to declare how many boxes, what they are made of and the net weight of the danger. 1 Fibreboard box x 2 kg is a clearer description. - Missing 24hr Emergency Tel # or the # is not complete with a dialing code.

- Certification statement – Number 1 reason for rejection, forgot to sign the declaration.

Section II shipments need no formal declaration, but the airline will still want to know they have batteries onboard. This is completed by your freight forwarder adding a statement on the airwaybill.

5.2 IMDG Dangerous Goods Declaration and Multimodal DGN

For sea freight, the IMDG form mirrors SOLAS requirements. Mandatory fields:

UN3481, LITHIUM ION BATTERIES CONTAINED IN EQUIPMENT, 9,- EMS code – always

F-A, S-Ifor lithium batteries. - Stowage/segregation –

Stowage category A. - Clear understanding of the weight of the batteries being shipped

- It is also common for shipping lines to require a 24hr Emergency Tel # on the dangerous goods note, due to the potential risk of carrying Lithium Batteries.

A properly completed Multimodal Dangerous Goods Note (DGN) can travel unchanged onto the ADR road leg providing it complies with the ADR, saving duplication. In the UK we have been provided with a template from the Maritime Coastguard Agency. See the template here

5.3 Road consignment note and driver instructions

ADR 5.4.1 allows the information to sit on a standard CMR. Minimum wording:

UN3090, LITHIUM METAL BATTERIES, 9, (E)

Add the number and kind of packages, total gross mass, and tunnel code if “E” routes apply. Provide written driver instructions describing fire-fighting measures and emergency contacts; many hauliers accept these as QR-coded laminated cards in the cab.

5.4 UN 38.3 Test Summary and Safety Data Sheet

The shipper must possess (not necessarily enclose) the UN 38.3 test summary for each cell type and make it available within 24 hours of a request. Safety Data Sheets are not legally required for finished batteries but remain best practice when shipping prototypes or custom packs.

5.5 Record retention and digital documentation tips

- All regulations: Dangerous Goods Notes & Shippers declarations should be kept for 3 months.

- Training Records should be kept in line with the UK Government HR Policies

- Use e-signature platforms approved by airlines and ports to cut paper delays and reduce transcription errors.

Master these documents and the rest of the lithium battery shipping regulations fall neatly into place.

6. Prepare the Shipment for Carrier Acceptance

The paperwork may look perfect on your screen, yet consignments still fall at the final hurdle if the carrier is not ready or the physical box fails a gate-side check. Carrier acceptance is therefore the moment of truth where all earlier steps under lithium battery shipping regulations are tested. Build a short buffer into your schedule so there is time to fix snags before the lorry door or aircraft hold closes.

6.1 Pre-alert the carrier and confirm special requirements

Most integrators and freight forwarders operate dangerous-goods booking windows—often 24 – 48 hours ahead for road and sea, and up to five days for air. Use the DG desk’s portal or email template to flag:

- UN number, packing instruction and section (IA/IB/II)

- Net and gross weights of batteries

- Route details, especially any transit airports with DG embargoes or special requirements

Some operators (e.g. FedEx “DG Ready”) run automated validation tools that will screen your data before a physical inspection. Remember that PI 965 Section IA and IB loads usually need written carrier approval, and peak-season embargoes on loose batteries can appear with little notice.

6.2 Inspection checklist before handover

Run a last-minute audit while the pallet is still in your warehouse:

- UN 38.3 test summary on file

- State-of-charge measured ≤ 30 % (if required)

- Correct UN-spec box or approved strong outer

- Cells & batteries individually protected against short-circuit

- Void fill tight; no movement when shaken

- Battery mark / label 9A clean and visible

- “OVERPACK” marking shown or repeated

- Shipper’s Declaration or Dangerous Goods note: signed, dated, legible

- Air waybill or CMR references DG status – freight forwarders & carriers

- Emergency phone number reachable 24/7

Tick every box and the acceptance clerk’s own list should mirror yours.

6.3 Handling rejected or non-conforming consignments

If the load is refused, isolate it in a designated DG quarantine area; never break the packaging seal on the ramp. Decide quickly whether to re-pack, re-route or scrap—airport storage can exceed £100 per pallet per day and demurrage at UK ports climbs just as fast. Document the incident and feed the lessons back into your SOPs so the same error does not reappear next week.

7. Train Your Team and Keep Compliance Up to Date

The most watertight procedures collapse if the people executing them do not understand why they exist. Lithium battery shipping regulations place legal responsibility on employers to train every worker whose job “directly affects” dangerous-goods safety. That ranges from the warehouse temp who tapes the carton to the export clerk who signs the Shipper’s Declaration. Regular, role-specific Battery training backed up by living procedures turns rules on paper into safe, repeatable practice.

7.1 Mandatory training requirements by mode

- Air (IATA DGR, Function Specific Categories):

- Function-based syllabus plus assessment every 24 months.

- Records must list syllabus, exam score and trainer approval number.

- Employers must complete a Competency Based Assessment

- Sea (IMDG Code 1.3):

- General awareness + job-specific modules; two-year refresher is industry norm.

- Shore-side staff at UK ports often need the port’s own induction on top.

- Road & rail (ADR/RID 1.3):

- Drivers transporting fully regulated batteries require an ADR licence.

- Drivers not ADR qualified need a Driver Dangerous Goods Awareness

- Warehouse and office staff need documented “general awareness” and “task-related” instruction.

- Postal & courier networks:

- Operators such as Royal Mail may demand their proprietary e-learning before granting account status.

7.2 Build robust SOPs and competence checks

- Map each task (e.g., battery identification, label application) to a short, pictorial work instruction.

- Issue laminated checklists that travel with the packing bench or handheld scanner.

- Run quarterly toolbox talks and spot audits; log findings and corrective actions.

- Capture tribal knowledge—video a senior packer demonstrating a tricky overpack closure and embed the clip in your LMS.

7.3 Monitor regulatory updates and future changes

Rules update every two years, sometimes faster:

- IMDG Amendment 42-24 enters force on 1 January 2026.

- IATA DGR 2026 tightens the state-of-charge proof requirements.

- The UK has hinted at post-2025 ADR divergence—watch the Department for Transport bulletins.

Assign one person as “DG watchkeeper” to subscribe to IATA, IMO, UNECE feeds and industry forums. A 10-minute scan each month can prevent a costly scramble when new lithium battery shipping regulations land on your desk.

8. Special Cases: Damaged, Waste, or Recalled Batteries

Not every shipment involves pristine, factory-fresh cells. When batteries are swollen, leaking, recalled, or ready for recycling, the normal reliefs in lithium battery shipping regulations disappear. These movements are viewed as higher-risk and therefore invoke additional controls, packaging codes, and in some cases outright bans—particularly for air transport. Treat them as a distinct workflow with its own SOPs and trained staff.

8.1 Definition and classification of damaged or defective batteries

A battery is “damaged” or “defective” when it shows signs such as swelling, dented casing, fluid leakage, or fails diagnostic tests. The UN number remains UN3480/81 or UN3090/91, but the Proper Shipping Name must be amended to include “DAMAGED/DEFECTIVE”. Expect carriers to request photos or an engineering report before booking. Seek expert advise if you are shipping these types of batteries.

8.2 Packaging provisions P908, LP904, and air restrictions

- ADR/IMDG: Use packing instruction P908 (packages) or LP904 (large packagings). Requirements include:

- Non-combustible, insulating filler (vermiculite, CellBlockEX).

- Watertight inner liner or sleeve.

- Rigid metal or UN-approved plastic outer capable of withstanding a 1.2 m drop.

- Air: ICAO/IATA prohibit damaged or recalled batteries unless the State of Origin and Operator grant an exemption. Where permitted, Packing Instruction PI 965/968 Section II does not apply; expect bespoke containment such as fire-proof battery boxes and temperature monitoring.

8.3 Waste batteries and producer responsibility

In the UK, movements to recycling facilities fall under the Waste Batteries and Accumulators Regulations 2009 and ADR Special Provision 636. Shipments meeting SP 636 threshold (≤333 kg lithium batteries per transport unit) are exempt from most Class 9 rules but must still:

- Use strong, stackable packaging that prevents short-circuit.

- Display the battery mark; omit Class 9 label if SP 636 applies.

- Travel with a waste transfer note instead of a DG declaration.

Partner with an authorised recycler and document every consignment to close the compliance loop.

Wrapping It Up

Compliant lithium battery shipping boils down to seven disciplined moves:

- Identify the exact chemistry and configuration.

- Pick the rulebook for every leg and follow the strictest clause.

- Calculate watt-hours or lithium content and stay inside quantity limits.

- Pack in the right UN-spec or strong outer, then mark and label precisely.

- Complete error-free documents and keep records for the statutory period.

- Book with the carrier early and pass their acceptance check first time.

- Refresh staff training and SOPs before the regulations change again.

Need hands-on practice or certification? Talk to the experts at Logicom Hub and ship with confidence.

Tel #: 0330 912 5041 / [email protected]